Manifolds play a crucial role in underfloor heating systems by efficiently distributing warmed water from your heat source throughout the network of pipes embedded in your floors. This guide will explore the operation of a manifold and how it ensures your home remains comfortably warm while optimising energy use.

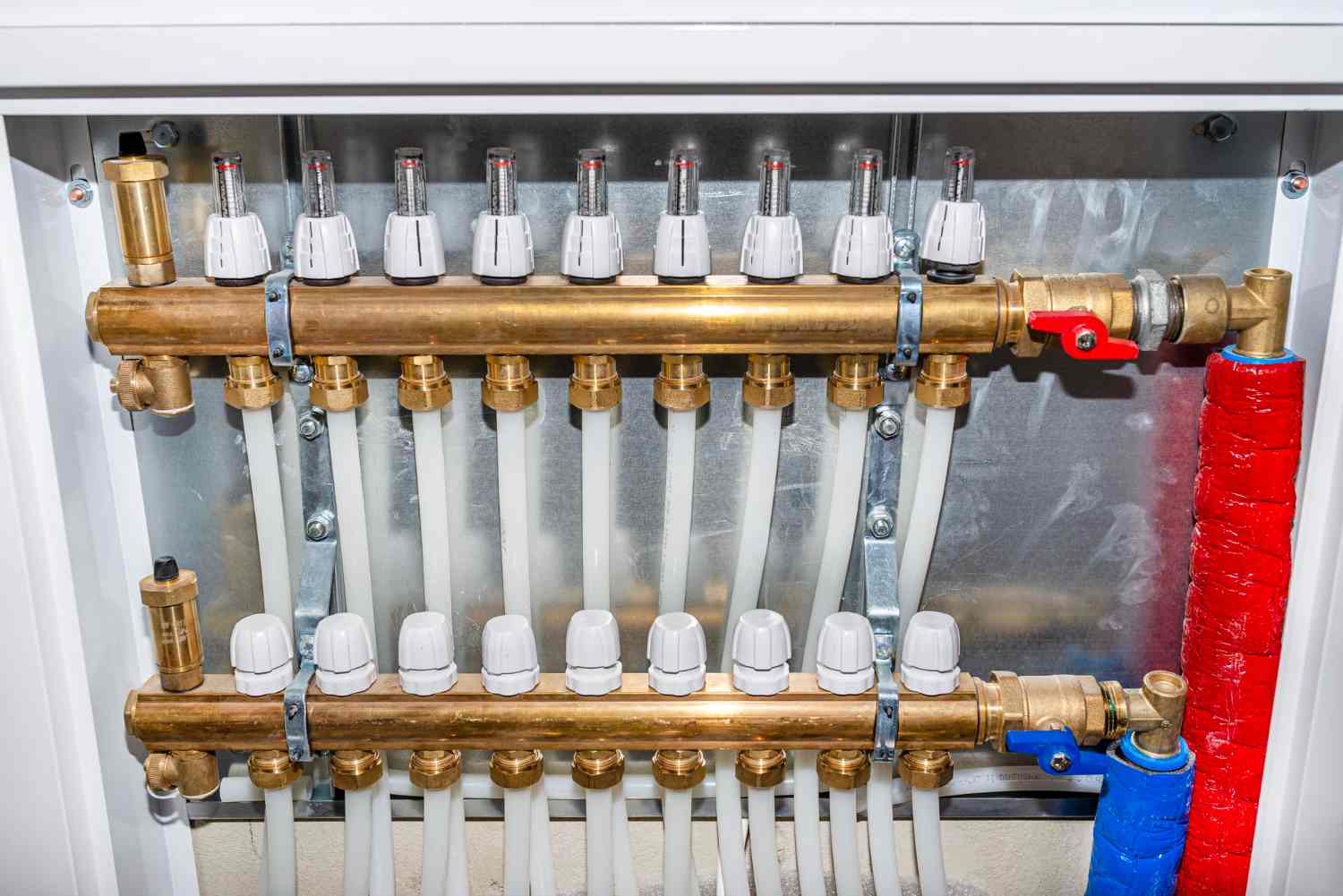

The underfloor heating manifold manages the flow and temperature of water throughout the circuits. In the following section, we’ve mentioned its key components:

A manifold system orchestrates the distribution of heated water throughout a UFH network for a consistent and comfortable temperature across the floor. Serving as the central hub of the heating setup, the manifold connects the supply and return lines, playing a crucial role in maintaining warmth throughout your home.

The system features two main components: the flow manifold and the return manifold. The flow manifold tracks the rate at which water circulates through each loop, while the return manifold manages the water returning from these loops. Each loop is equipped with a valve that can be opened or closed. These valves are operated by actuators, which are controlled by thermostats to adjust the temperature precisely.

Manifolds are versatile in their setup. They can be directly connected to a pumped heat source or used alongside a pump or a water temperature mixing unit for more controlled heating. Manifolds can be tested at pressures up to 6 bar for system integrity, though they typically operate at pressures lower than 3 bar.

Proper installation of an underfloor heating manifold is essential for the system to function optimally. Here’s a step-by-step approach to ensure a successful setup:

When installing an underfloor heating manifold, following best practices can make a significant difference in functionality and ease of maintenance:

When determining the best spot for your underfloor heating manifold, consider the following factors:

Underfloor heating manifolds are pivotal in optimising the efficiency of your heating system beyond merely distributing warmth. Let’s explore how they contribute to energy savings: